Approximately 45 million Americans get their water from a well. Unlike city water, well water is not treated with chlorine or chloramine by a municipal plant. Instead, homeowners must ensure the appropriate systems are in place to make their water safe. To allow for well water to enter a home, a well pump must be installed to push water from the ground up into a home’s plumbing. Well pumps allow for a consistent flow of water into a home while making the process as energy efficient as possible. However, knowing which well pump is right for a home can be tricky when the time comes to install a pump. In this article, you can find information on what well pumps are, how they work, the types of well pumps, and how to choose the right well pump for your property.

What is a well pump?

A well pump is a device that draws water from a well and pushes or pulls it into a well storage tank. Depending on the type of pump, it can be installed in the home, in an outbuilding, or in the well itself. A submersible pump uses impellers to draw water in and push it up a pipe, while jet and centrifugal pumps use impellers to create suction that pulls water up from underground. All these pumps work better than the others under certain conditions and carry different initial and ongoing maintenance costs. Read on to learn more about these types of pumps.

How does a well pump work?

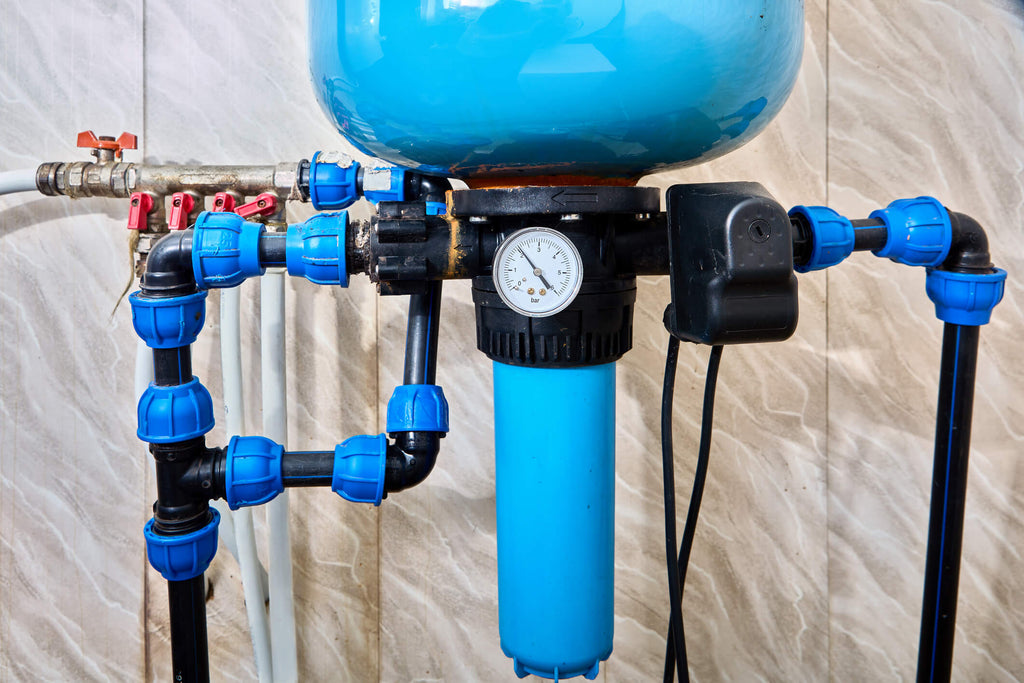

Well pumps can work in one of two ways: by pushing water up a pipe or using suction to pull it from underground. Well pumps are activated by a well pressure switch, a device that sends a signal to the pump when water pressure inside a well pressure tank becomes too high or low. The pressure switch lets the pump run as little as possible to elongate its lifespan. When the water level inside a well pressure tank becomes low, the pump activates and begins to fill the tank. Once the tank reaches a preset pressure after filling up, the switch signals the pump to turn off. This ensures the pump only turns on and off when it needs to, preventing issues like overheating and short-cycling that can cause the pump to fail prematurely.

Learn more: What is a well pressure switch?

How much do well pumps cost?

Even without labor, submersible pumps are typically more expensive than jet and centrifugal pumps. The price of submersible pumps ranges between $400 and $2000, while jet pumps typically cost anywhere from $300 to $1200. Centrifugal pumps, which can only be used for specific applications, cost only $100 to $500. Installation costs bring the total price of most well pumps up to the range of $1300 to $5300. The cost of the pump and its installation depend heavily on the type of pump being installed and the depth of the well. Submersible pumps typically cost more to install as they are used in deep well applications and must be installed near the bottom of the well. However, since most wells in the United States are 100 feet or deeper, they are often the best investment for your well despite their higher initial cost. Single-drop jet pumps and centrifugal pumps are the most inexpensive type of pump, while double-drop jet pumps account for the upper range of jet pump costs.

How much does well pump maintenance cost?

The average maintenance cost on a well pump is about $900, typically ranging between $300 and $1500. It is important to check other components, such as the pressure tank and pressure switch, of the well system that could lead to pump failure. Some units, such as the pressure switch, can cause the pump to malfunction but are less expensive to replace or repair than the well pump itself.

Types of well pumps

There are three main types of pumps used for wells: submersible, jet, and centrifugal.

Submersible well pumps

Submersible well pumps are the most common residential well pump in the United States because of their practicality in most well types. Submersible pumps are installed inside a well and rely on water covering the entire pump. The motors of these pumps use impellers to draw water in and push it up a pipe and into a pressure tank. Submersible pumps are water-tight and durable, necessitating little maintenance. The most common damage to submersible pumps involves corrosion of the drive seals from sand and other sediments. When maintenance is required, the pump must be brought out of the well for repairs. The added labor cost this process requires increases the overall maintenance price of submersible pumps.

Advantages of submersible pumps

- Can be used in practically any well

- Energy efficient

- Durable

Disadvantages of submersible pumps

- More difficult and expensive maintenance

- Susceptible to corrosion in sand-rich wells

- More expensive

Jet well pump

Jet pumps operate above the well outside of the water. They can be installed inside the home or in a dedicated well house. Jet pumps use a suction pipe to provide a well pressure tank with water. Because jet well pumps operate outside of water, they are more easily accessible for maintenance than submersible pumps and are not susceptible to damage from sand and other sediments in wells. Jet pumps are available in two configurations: single-drop and double-drop.

A single-drop jet pump, also known as a shallow well jet pump, draw water from wells fewer than 25 feet deep. These pumps must be installed indoors, either inside the home or in an outbuilding. Some single-drop jet pumps may be advertised as “self-priming,” but they still must be manually primed after initial installation and each power loss. Running a dry pump risks overheating the pump and causing irreparable damage.

A double-drop jet pump, also called a deep well jet pump, contains more impellers and diffusers than a single-drop pump. These units use a jet injector that allows water to be suctioned in wells as deep as 110 feet. Unlike single-drop jet pumps, double-drop jet units are installed inside the well while the impeller motor operates above ground.

Advantages of jet pumps

- Easy and infrequent maintenance

- Not susceptible to damage caused by sediment

- Can be used for irrigation and gardening

- Less expensive

Disadvantages of jet pumps

- Less efficient as depth increases

- Must be primed

- Limited to wells shallower than 25 feet (single-drop) or 110 feet (double-drop)

- Less energy efficient

Centrifugal well pumps

Centrifugal pumps use impellers to draw water into the pump and rotational energy to expel it out an outlet. These pumps are very small and, as a result, can only draw water from shallow wells. Wells deeper than 25 feet must be equipped with either a submersible pump or a double-drop jet pump to ensure sufficient power is available to draw out water. Centrifugal pumps do not have drive seals, preventing corrosion from sand and other sediments from damaging the unit. Like shallow well jet pumps, centrifugal pumps are generally inexpensive, and their corrosion resistance allows for infrequent maintenance. This makes centrifugal pumps a cost-effective option for shallow wells.

Advantages of centrifugal well pumps

- Inexpensive

- Simple and infrequent maintenance

- No corrosion risk

Disadvantages of centrifugal well pumps

- Only useful in wells shallower than 25 feet

What is the best type of well pump?

The depth of your well determines which well pump type is best suited for your home. For wells shallower than 25 feet, either a single-drop jet pump or centrifugal pump is the best option. For wells between 25 and 110 feet deep, a double-drop jet pump will provide the optimal pump power. Finally, for wells between 110 and 400 feet deep, a four-inch submersible pump should be installed. The size of your well pump is determined by the size of your home. The ideal well pump delivers water with appropriate pressure while maintaining an efficient run cycle.

How to size a well pump

To find the right size well pump for your home, you need to calculate the gallons per minute required during peak periods of water usage. This involves counting the number of fixtures in your home. A two-bathroom home typically contains about 12 fixtures between each bathroom, laundry room, kitchen, other appliances, and any outdoor spigots. A typical well pump size for this example home would be about 8 to 12 gallons per minute (gpm). An appropriately sized well pump is crucial to the operation and overall performance of your pump. An under-sized pump will not be able to meet your water demands and risks failure from being engaged too frequently. An over-sized well pump can lead to higher energy costs resulting from inefficiency and can also lead to performance issues.

If the amount of water available in a well is a concern, then your pump may not be able to deliver an appropriate amount of water during periods of peak demand. This problem can be offset by incorporating a large enough well pressure tank. A larger storage capacity can help your home get through peak periods in instances where there is not enough available water to draw from your well.

Learn more: How to size a well pressure tank | Well pressure tank problems and how to fix them

If you have any further questions, please do not hesitate to contact us.